The evolution of technology from the past to the present

Technology history is the progression of organised methods for creating and performing things over time. The word “technology,” which combines the Greek words techn, “art, craft,” and logos, “word, speech,” refers to a discussion of the fine and applied arts in Greece. It was exclusively used to discuss the applied arts when it first debuted in English in the 17th century, but through time, the term came to refer to these “arts” specifically. Early in the 20th century, in addition to tools and machines, the phrase had come to encompass a wide range of methods, procedures, and concepts. Technology was described as “the means or activity by which man strives to change or manage his environment” by the middle of the 20th century. Observers who highlight how difficult it is to distinguish between technological activity and scientific research have questioned even such broad definitions.

Prehistory

Stone Age

All humans lived in a lifestyle with few permanent settlements and few tools for the majority of the Paleolithic, which is the term used to describe the Stone Age. The first significant technologies were related to food preparation, hunting, and survival. The invention of fire, clothing, and stone tools and weaponry was a great technological advance during this time.

Long before the 300,000-year-old Homo sapiens emergence, our ancestors have been employing stone and other tools.

The earliest confirmed instance of tool use, which dates back 2.5 million years, was discovered in Ethiopia’s Great Rift Valley. The Oldowan “industry”—the first techniques for creating stone tools—dates to at least 2.3 million years ago. The Paleolithic period, sometimes known as the “Old Stone Age,” covers the entirety of human history up to the advent of agriculture around 12,000 years ago.

The transition from a nomadic lifestyle to settlement and cultivation can be deduced from a variety of archaeological findings, despite the absence of written records for Paleolithic cultures. Such proof includes prehistoric artefacts like the Venus of Willendorf, old tools, and cave paintings. Direct evidence is also provided by human remains, which can be seen in the study of mummies and the analysis of bones. Significant inferences regarding the way of life, culture, and technology of many prehistoric peoples have been made by scientists and historians.

Ancient

Copper and bronze Ages

Before copper smelting was known, copper was used because metallic copper may be found on the surface of worn copper ore deposits. It is thought that copper smelting first appeared when pottery kiln technology enabled high enough temperatures. When copper ore deposits are smelted, arsenical bronze is produced, which can be sufficiently work-hardened to be appropriate for making tools. The concentration of certain elements, such as arsenic, increases with depth in copper ore deposits.

Tin is a metal that is found in relatively few deposits worldwide, therefore it took a while before real tin bronze became commonplace. Tin and copper are an alloy that makes bronze. Due to its mechanical advantages over stone, such as strength and ductility, as well as the ability to be cast in moulds to create intricately shaped things, bronze represented a significant improvement over stone as a material for creating tools. Better tools and bronze nails dramatically improved shipbuilding technology. The ancient method of fastening hull board boards with thread braided through drilled holes was replaced by the use of bronze nails. Long-distance trade and the development of civilization were made possible by better ships.

Iron Age

Prior to the invention of iron smelting, the only iron came from meteorites and was typically recognised by its nickel content. Although meteoric iron was precious and rare, it was occasionally utilised to produce tools and other items, like fish hooks.

Iron smelting technique was adopted during the Iron Age. In most cases, it took the place of bronze and allowed for the production of tools that were stronger, lighter, and more affordable to build than their bronze equivalents. Compared to copper and particularly tin ores, the raw resources used to create iron, such as ore and limestone, are far more plentiful. As a result, iron was made everywhere.

Steel and pure iron could not be mass produced due to the high temperatures needed. The crucibles and moulds required for melting and casting had not yet been produced, despite the fact that furnaces could reach melting temperatures. To lower the carbon content of iron in a fairly manageable manner, steel could be made by forging bloomery iron, but the steel created by this process was not uniform.

China

Numerous first-ever discoveries and advancements were achieved by the Chinese. Early seismological detectors, matches, paper, the raised-relief map, the double-action piston pump, cast iron, water-powered blast furnace bellows, the iron plough, the multi-tube seed drill, the wheelbarrow, the parachute, the compass, the rudder, the crossbow, the South Pointing Chariot, and gunpowder are a few examples of China’s major contributions to technology. In order to extract brine for creating salt, China pioneered deep well drilling. Natural gas was produced by some of these 900-meter-deep wells and utilised to evaporate brine.

Block printing, moveable type printing, phosphorescent paint, limitless power chain drive, and the clock escapement mechanism are some of the other Medieval Chinese discoveries and inventions. Nearly 200 years after the creation of gunpowder, the solid-fuel rocket was created in China in the year 1150. Gunpowder served as the fuel for the rocket. The Chinese monarchs of the Ming Dynasty also dispatched sizable fleets on marine expeditions, some of which reached Africa, decades before the Western age of exploration.

Roman Empire

Between the first century BC and the first century AD, the Roman Empire grew from Italy to encompass the entire Mediterranean region. The Eastern Roman provinces in the Balkans, Asia Minor, Egypt, and the Levant were its most sophisticated and economically successful territories outside of Italy, with Roman Egypt in particular being the richest Roman territory outside of Italy.

The Roman Empire created laws allowing for individual ownership, advanced stone masonry technology, advanced road-building (surpassed only in the 19th century), military engineering, civil engineering, spinning and weaving, and a number of different machines, such as the Gallic reaper, that helped to increase productivity in many areas of the Roman economy. The Roman Empire also developed an intensive and sophisticated agriculture, improved upon existing iron working technology, expanded upon it, and developed intensive and sophisticated agriculture. Roman architects and engineers were the first to construct enormous vaults, domes, amphitheatres, aqueducts, public baths, genuine arch bridges, harbours, reservoirs, and dams all over their Empire. Concrete, glassblowing, and the book (Codex) are among notable Roman inventions.

Rome was built on a volcanic peninsula with sand that had sufficient crystalline granules, which made for particularly durable concrete. Some of their structures continue to stand today after 2000 years.

Hero of Alexandria, a Roman Egyptian inventor, opened up new opportunities for harnessing natural forces when he was the first to experiment with a wind-powered mechanical device (see Heron’s windwheel) and even made the first steam-powered device (the aeolipile). In addition, he created a vending machine. However, rather than being useful devices, most of his inventions were toys.

Irrigation

The technologies used to produce food also demonstrated several advancements over Neolithic practises, with systematic irrigation standing out as an especially notable one. The two great river systems, the Nile and the Tigris-Euphrates, which both irrigated the ground with their annual floods and regenerated it with the rich alluvium they deposited, were extremely important to the civilizations of Egypt and Mesopotamia. The Nile flooded frequently each summer, and the civilizations that emerged in its valley were among the first to master basin irrigation, which involved holding back floodwater after the river had subsided as long as possible so that fertilised soil could produce a crop before the next season’s floods. Because the floods in the Tigris-Euphrates basin were less predictable, more severe, and arrived earlier than those in the northward-flowing Nile, the irrigation problem there was more complicated. Additionally, they transported additional alluvium, which often clogged irrigation channels. The Sumerian irrigation engineers’ job was to divert water from the rivers during the summer, impound it, and then distribute it gradually to the crops. The Sumerian technique finally failed because it caused the land to become too salty, which reduced its fertility. However, both systems relied heavily on social control, necessitating expertise in staking out the land and a complex legal framework to assure fairness in the allocation of priceless water. The construction of canals, aqueducts, and water-raising devices like the shadoof—a balanced beam with a counterweight on one end and a bucket to lift the water on the other—as well as the utilisation of dikes, embankments, and other complicated technical techniques were also necessary for both systems.

Building

The biggest advancements in building technology didn’t involve any particular innovations so much as the volume of operations. Mesopotamian communities from the late Stone Age had already created a lot of structures out of sun-dried brick. Their successors carried on the practise but increased the scale to build the enormous square temples known as ziggurats. These featured a brick core and face, with regular pilasters set into the brickwork to break up the sloping facing walls. The entire construction rose in two or three stages to a temple at the summit. The first people to use brick manufactured from local clay to construct columns were the Sumerians, who also provided the scribes’ writing implements.

Khafre’s pyramid

While good construction stone was easy to come by in Egypt, builders used it to create the magnificent structures of Egyptian culture, such as the pyramids and temples, which still stand today. Stones were hauled up the structure’s various levels using rollers, ramps, and balancing levers modified from the water-raising shadoof. As can be seen from the exact astronomical alignments, the stones were fashioned by experienced masons and carefully positioned by priest-architects who were clearly capable mathematicians and astronomers. The arduous labour of construction was undoubtedly performed by legions of slaves, which helps to explain both the successes and shortcomings of early civilizations. Stones were hauled up the structure’s various levels using rollers, ramps, and balancing levers modified from the water-raising shadoof. As can be seen from the exact astronomical alignments, the stones were fashioned by experienced masons and carefully positioned by priest-architects who were clearly capable mathematicians and astronomers. The arduous labour of construction was undoubtedly performed by legions of slaves, which helps to explain both the successes and shortcomings of early civilizations. Although their status as a subject race might last forever, slaves were typically one of the results of military conquest, which presumes a period of successful territorial expansion. For the large-scale construction projects that have been outlined, slave populations supplied a skilled and affordable labour force. The availability of slave labour, on the other hand, inhibited technical advancement, a social truth that goes a long way toward explaining the relative stasis of mechanical invention in the ancient world.

Exploration Era

With the European colonisation of the Americas, symbolised by Francis Bacon’s New Atlantis, the Age of Exploration was made possible by an improved sailing ship called the nau or carrack. Pioneers like Vasco da Gama, Cabral, Magellan, and Christopher Columbus travelled the globe in quest of new trade routes for their commodities and connections with Africa, India, and China to reduce the journey in comparison to conventional overland routes. They created new maps and charts, allowing subsequent seamen to explore farther and more confidently. However, because of the longitude issue and the lack of reliable chronometers, navigation was often difficult. The civil code concept was lost after the period of the Ancient Greeks until it was revived by European powers.

The urban revolution (c. 3000–500 BCE)

The technical progress that has thus far been described occurred gradually over a long period of time, in response primarily to the most fundamental social demands—the need for food and shelter—and with little social capital available for anything other than meeting these requirements. However, a significant cultural shift started to happen in a few favourable geographic locations around 5,000 years ago. In addition to creating new resources and requirements, it also significantly increased technological innovation. It marked the start of the city’s creation.

Craftsmen and scientists

copper finial

A population increase was made possible by the New Stone Age’s collected agricultural knowledge, and as a result, there was a greater demand for a variety of goods made by skilled craftspeople. Among these artisans were several metalworkers, first those who worked with metals that were easily obtained in metallic form, and in particular the soft metals, like gold and copper, which could be shaped by beating. Then it was discovered that it was possible to remove some metals from the ores in which they typically occur. The carbonate of copper known as malachite, which was then already in use as a cosmetic and easily converted to copper in a strong fire, was likely the first such substance to be employed. It is impossible to pinpoint the exact moment and location of this discovery, but the effects were profound. It prompted the quest for further metallic ores, the advancement of metallurgy, the promotion of trade in order to get particular metals, and the continued refinement of specialised talents. Due to its reliance on trade and manufacturing, it made a significant contribution to the development of urban societies and the birth of the first civilizations.

The early Metal Age replaced the Stone Age, marking the start of a new era in the history of humanity.

According to a pretty wide consensus, civilization is made up of a sizable society with a shared culture, stable communities, and complex institutions, all of which require a basic understanding of literacy and numeracy. In the earliest civilizations, mastery of the civilised arts was a rare endeavour and very certainly the tightly guarded property of a priestly caste. But even if just a small portion of people had these abilities, their very existence is important since it made it possible to record and transfer information, substantially expanding the potential for invention and speculative thought.

Technology had previously existed independently of science, but by the time of the first Sumerian astronomers, who plotted the motion of the celestial bodies with astounding accuracy and used their observations to base calculations about the calendar and irrigation systems, the potential for a productive partnership between science and technology had emerged. The initial benefits of this relationship were shown in vastly better capacities for measuring land, weighing, and keeping time—all practical talents that are crucial to any complex civilization and impossibly difficult to imagine without reading and the earliest forms of scientific observation. The first civilizations appeared in the Nile and Tigris-Euphrates valleys with the development of these talents in the third millennium BCE.

Industrial Revolution Prior

Mine pumping with a Newcomen steam engine

The stocking frame, created in 1598, raised a knitter’s knot production from 100 to 1000 per minute.

With horse-powered bucket and chain pumps and wooden piston pumps, mines were getting deeper and costing more money to drain. Up to 500 horses were employed in some mines. The Savery steam pump (1698) and the Newcomen steam engine superseded horse-powered pumps (1712).

Industrial Revolution (1760–1830s)

The inexpensive energy in the form of coal, which was produced in ever-increasing quantities from Britain’s plentiful resources, propelled the revolution. The creation of machine tools, the steam engine, and advancements in mining, metallurgy, and transportation are what define the British Industrial Revolution.

Before the development of spinning and weaving machines, yarn was spun on spinning wheels and cloth was woven on looms that were controlled by hand and foot. Three to five spinners were required to supply one weaver. A lack of spinners resulted from the flying shuttle’s creation in 1733, which increased a weaver’s output by twofold. Invention of the wool spinning frame occurred in 1738. The spinning jenny was a device with numerous spinning wheels that was created in 1764, however it only produced thread of poor quality. Compared to the spinning jenny, the water frame, which Richard Arkwright designed in 1767, generated thread of higher quality. A superior thread was created by the spinning mule, which Samuel Crompton invented in 1779. Edmund Cartwright created the power loom in 1787.

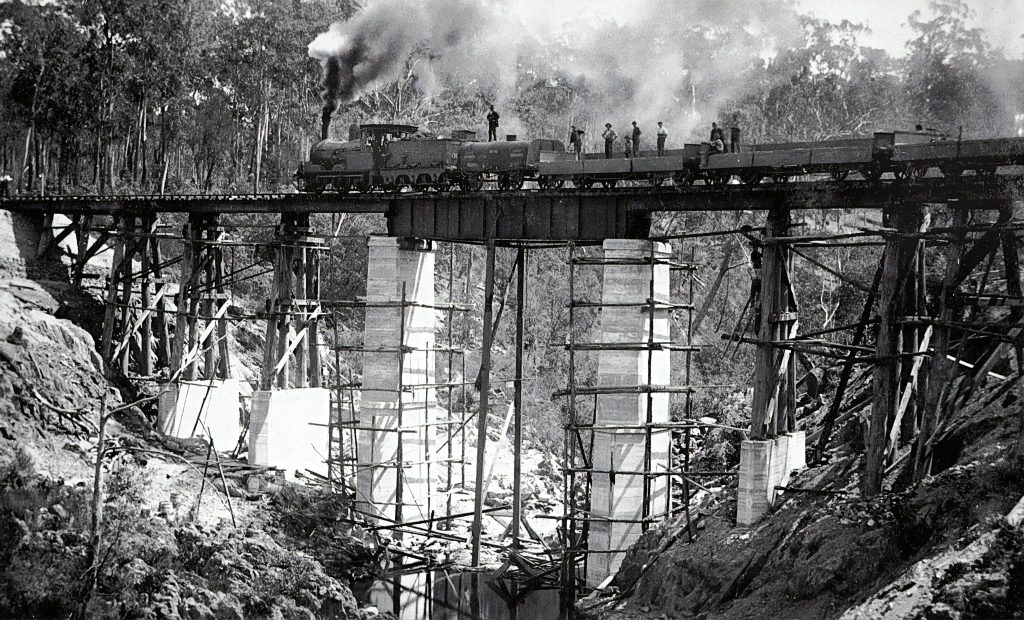

The Steel Bridge

The steam engine was used to power blast bellows in the water-limited iron, copper, and lead industries in the middle of the eighteenth century. These businesses, some of which utilised steam engines for mine pumping, were situated close to the mines. Cast iron blowing cylinders were created in 1768 because leather bellows couldn’t withstand the power of steam engines. Because steam-powered blast furnaces were able to reach greater temperatures, more lime could be added to the iron blast furnace feed. (At the previously employed temperatures, lime-rich slag was not freely moving.) Sulfur from coal or coke fuel reacts with the slag when the lime ratio is high enough, protecting the iron from contamination.

Coal and coke were more readily available and cheaper fuels. As a result, during the final decades of the 18th century, iron output increased dramatically. The conversion of coal into coke powered blast furnaces at higher temperatures and produced cast iron in far greater quantities than before, enabling the construction of a variety of buildings like The Iron Bridge. Although it remained to be an important source of energy, the availability of cheap coal freed the industry from the constraints of the mills’ reliance on water.

The preserved Rocket

The steam engine contributed to the mines’ being drained, increasing access to further coal deposits and coal production. Locomotives were made possible with the advent of the high-pressure steam engine, and a revolution in transportation ensued. Both steamboat and railroad transportation utilised the steam engine, which had been around since the early 18th century. The Rocket locomotive created by Robert Stephenson was one of the first functioning locomotives used on the Liverpool and Manchester Railway, the world’s first purpose-made railroad, when it first opened in 1830.

The period of continuous mass production began in 1803 when all-metal machines at the Portsmouth Block Mills began producing ships’ pulley blocks. In the first decade of the century, engineers started using machines to make parts, most notably Richard Roberts and Joseph Whitworth. Early in the 19th century, the United States Federal arsenals saw the creation of interchangeable parts through what is now known as the American system of manufacture. By the end of the century, interchangeable parts were widely used in the guns business.

Century 21

In the first decade of the twenty-first century, research is still being done on quantum computers, gene therapy (introduced in 1990), 3D printing (introduced in 1981), nanotechnology (introduced in 1985), bioengineering/biotechnology, nuclear technology, advanced materials (such as graphene), the scramjet and drones (along with railguns and high-energy laser beams for military uses), superconductivity, the memristor, and green technologies such as alternative.

Between 1998 and 2008, the Large Hadron Collider, the largest single machine ever built, was developed. Better equipment, such as bigger particle accelerators like the LHC and better neutrino detectors, are anticipated to further our understanding of particle physics. Underground detectors are used to look for dark matter, and observatories like LIGO have begun to find gravitational waves.

The science of genetic engineering is developing, and epigenetics’ significance for inheritance and development is also being better understood.

Additionally, brand-new spacecraft and technologies are being created, such as the SpaceX Dragon 2 and the Boeing Orion. New, more powerful space telescopes have been developed, such as the Colossus Telescope and the James Webb Space Telescope, both of which were sent into orbit in December of 2021. NASA and ESA are planning a human mission to Mars for the 2030s after completing construction of the International Space Station in the 2000s. An electro-magnetic thruster for spacecraft propulsion called the Variable Specific Impulse Magnetoplasma Rocket (VASIMR) is anticipated to undergo testing in 2015.

Breakthrough Initiatives and renowned physicist Stephen Hawking hope to send the first spacecraft to visit another star in the 2030s. It will be made up of a number of super-light chips propelled by electricity and should be able to send back images of the Proxima Centauri system and, possibly, the planet Proxima Centauri b by the middle of the century.

When Mike Melvill stepped outside of the solar system on June 21, 2004, it marked the beginning of crewed commercial spaceflight.